A heat exchanger is a device used to transfer heat between one or more fluids. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact.

They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment etc.

Following is different types of heat exchange is todays for different industrial application –

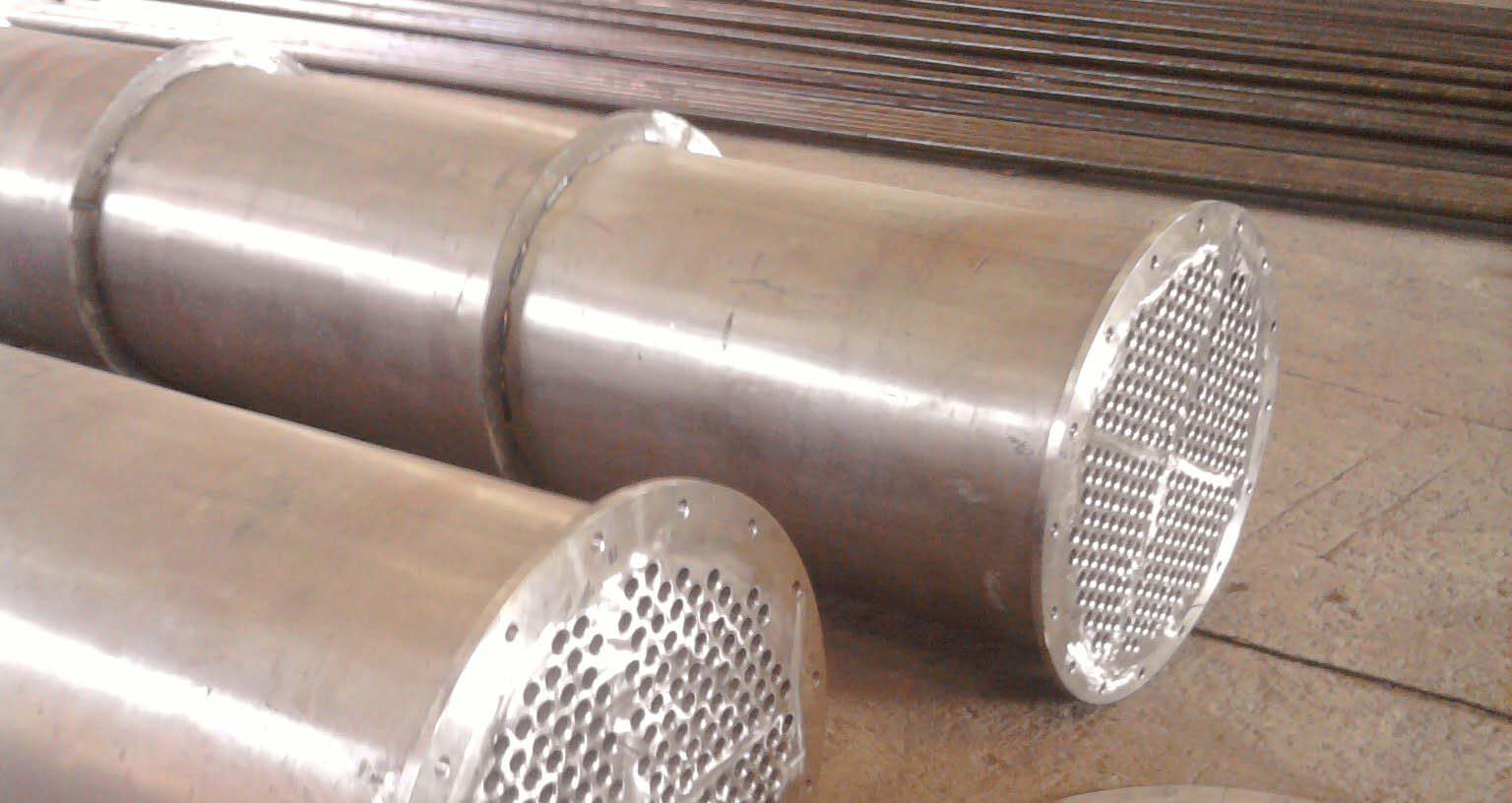

1. Tubular heat exchanger (VRS Provide)

2. Plate heat exchanger

VRS Industries provide only tubular Heat Exchanger.

It is most widely used types of heat exchanger and specially designed for the thermal treatment of low to high-viscosity products as well as products containing particles, pulp and fibers.

It consists of no of parallel stainless steel tubes mounted concentrically creating annular spaces for fluids to flow in a counter current manner. One fluid flow inside the tube (tube side) and one is outside the tube (shell side) so it’s called shell & tube heat exchanger.

Application –

1. Dairy Industries

2. Beverage Industries

3. Food Processing Industries

4. Pharmaceutical Industries

5. Chemical Industries